Basic Info

Model No.:YY–ARM—002

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Cutting Mode:Servo Tracking Cutting

Way Of Driven:Gear

Forming Speed:0-45m/min

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

Metal Angle Roll Forming Machine

Metal ceiling Light Keel Roll Forming MachineCeiling Tee bar Making machine Light Keel roll forming machine

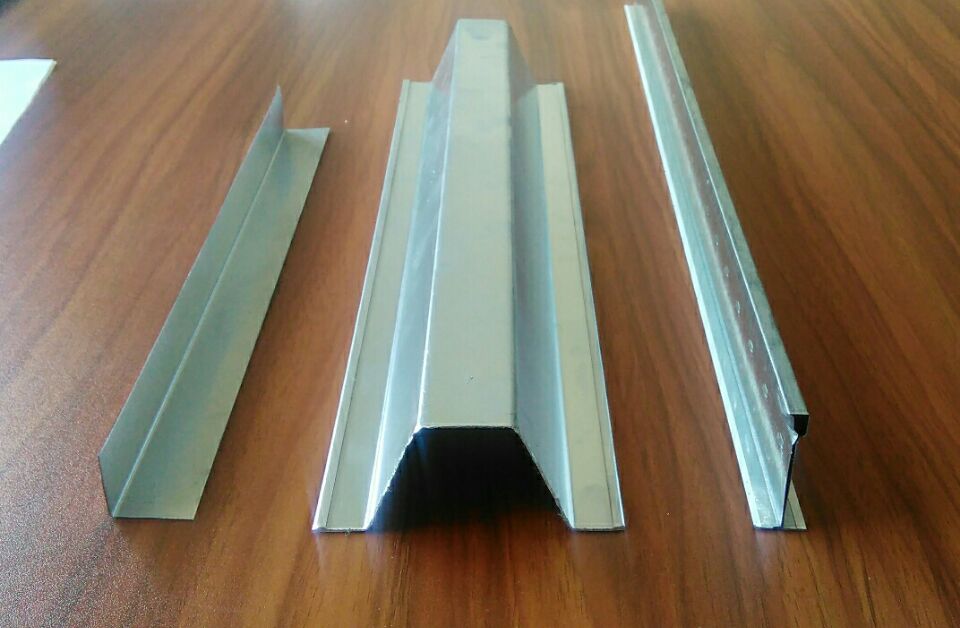

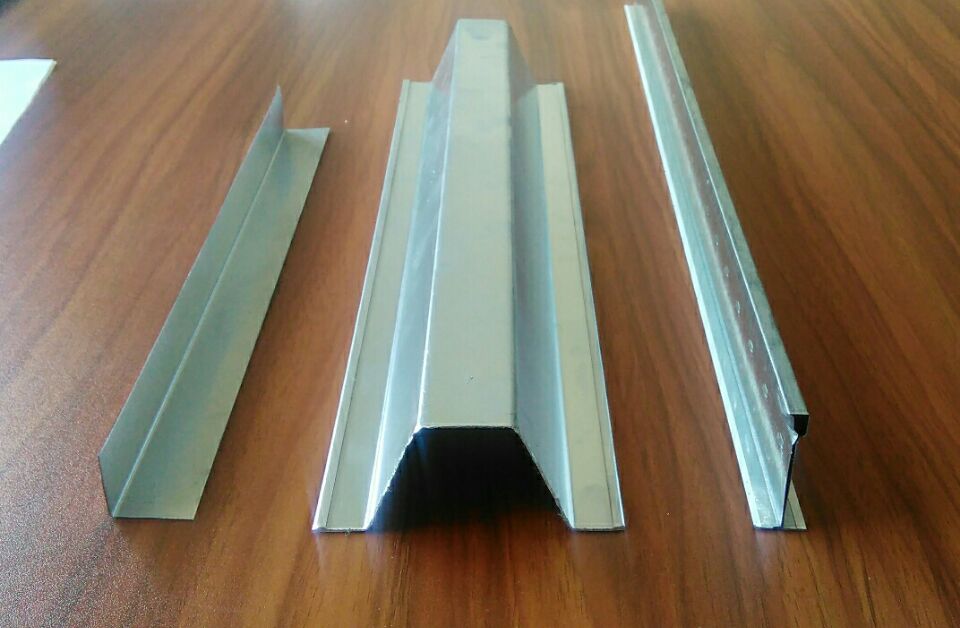

Angle Channel Machineis a strip of raw materials, through continuous cold rolling molding, production of complex cross-section profiles, Automatic Angle Roll Forming Machine consists of decoiler, guide rack, forming hosts, calibration device, cut-off part, receiving station, composed of electrical control and so on. Metal Angle Roll Forming Machine is easy to use, easy to operate and so on.

Working process:

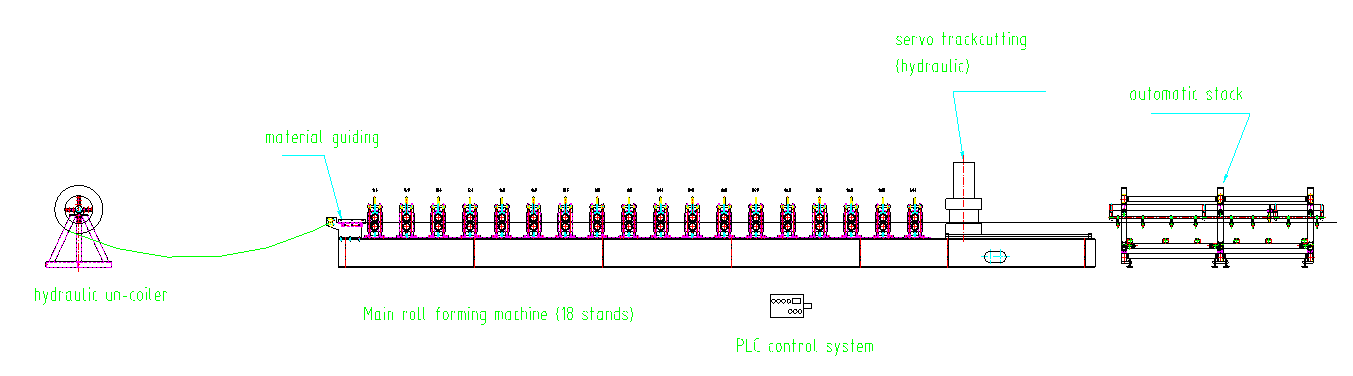

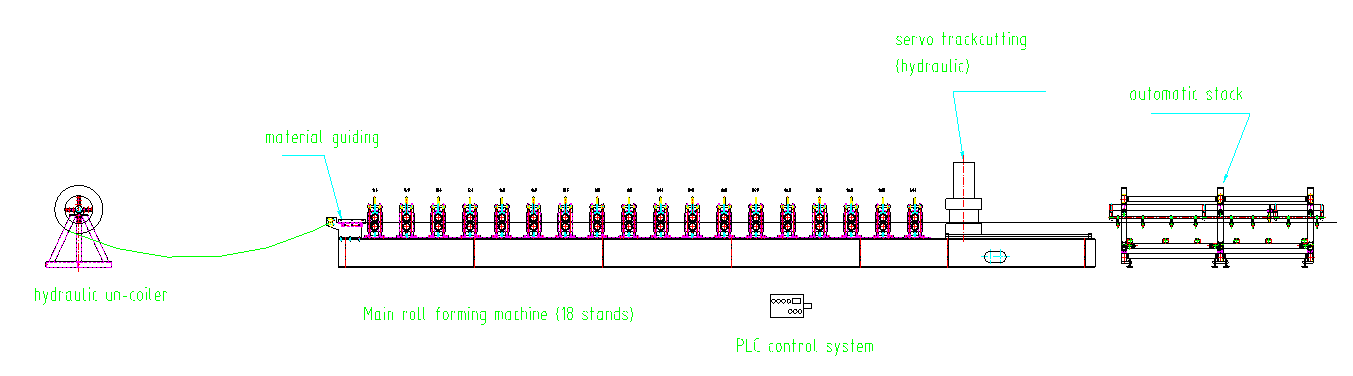

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 0-45m/min(without punching) |

| Rollers | 12 rows |

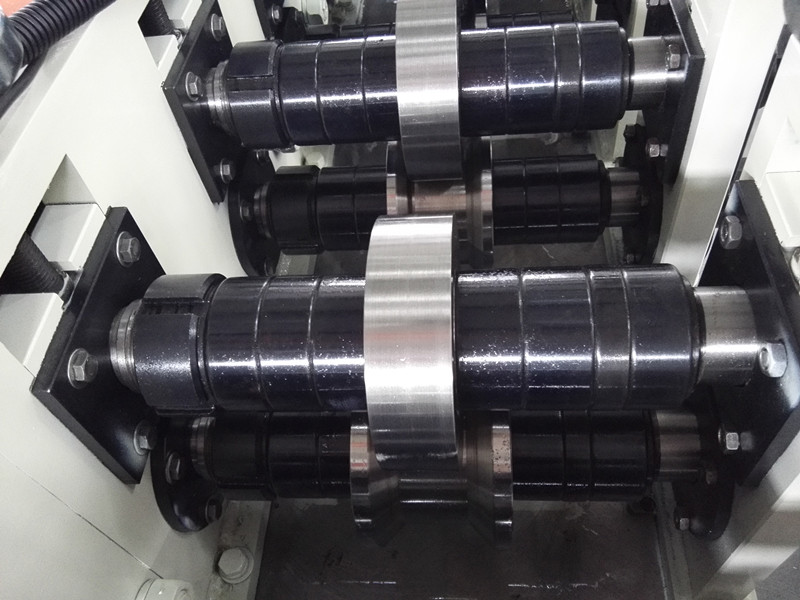

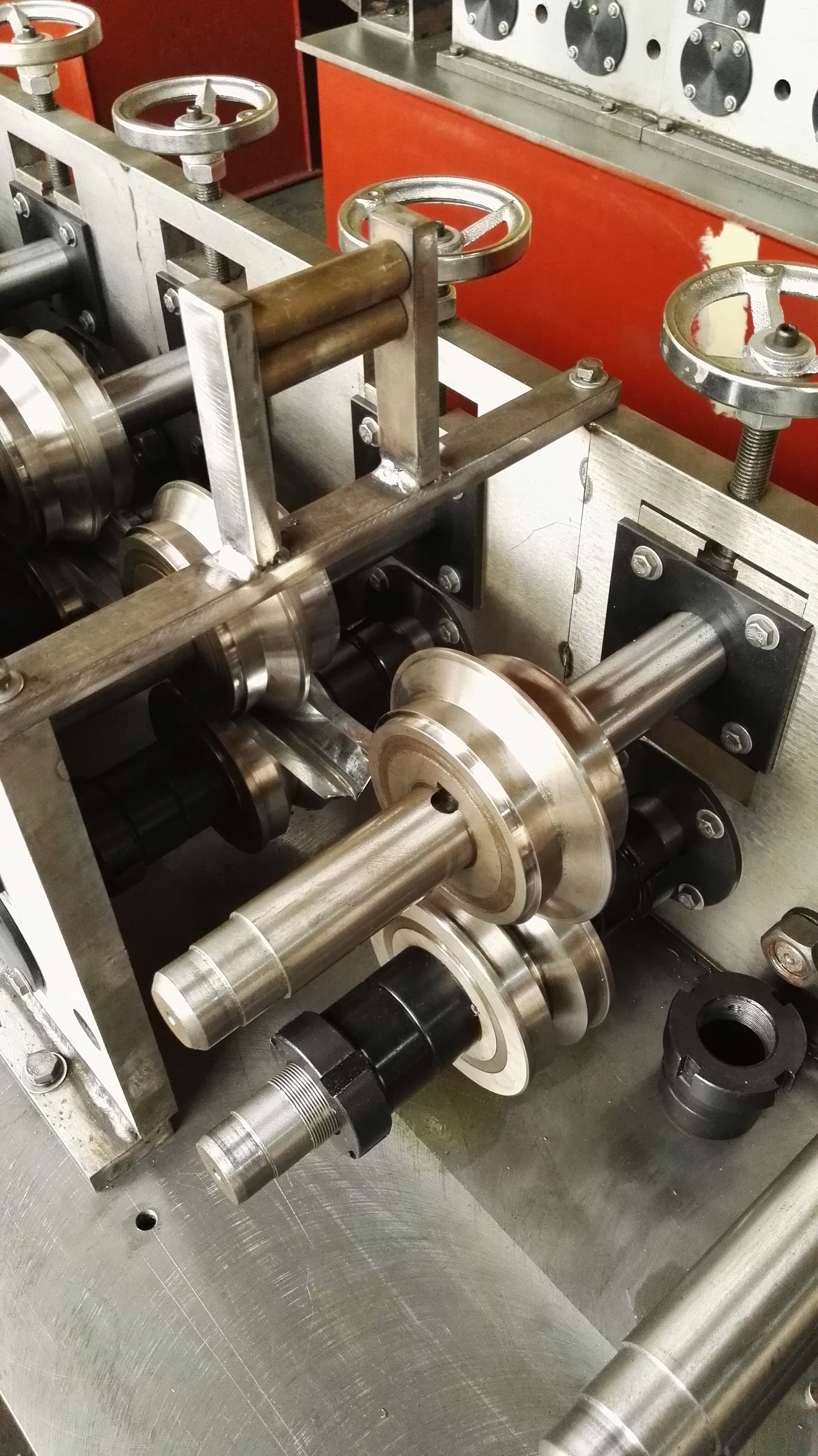

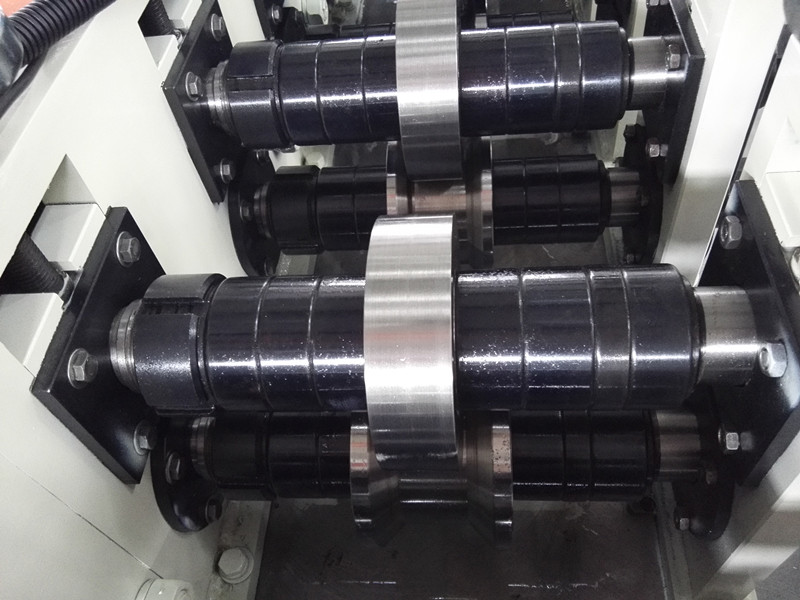

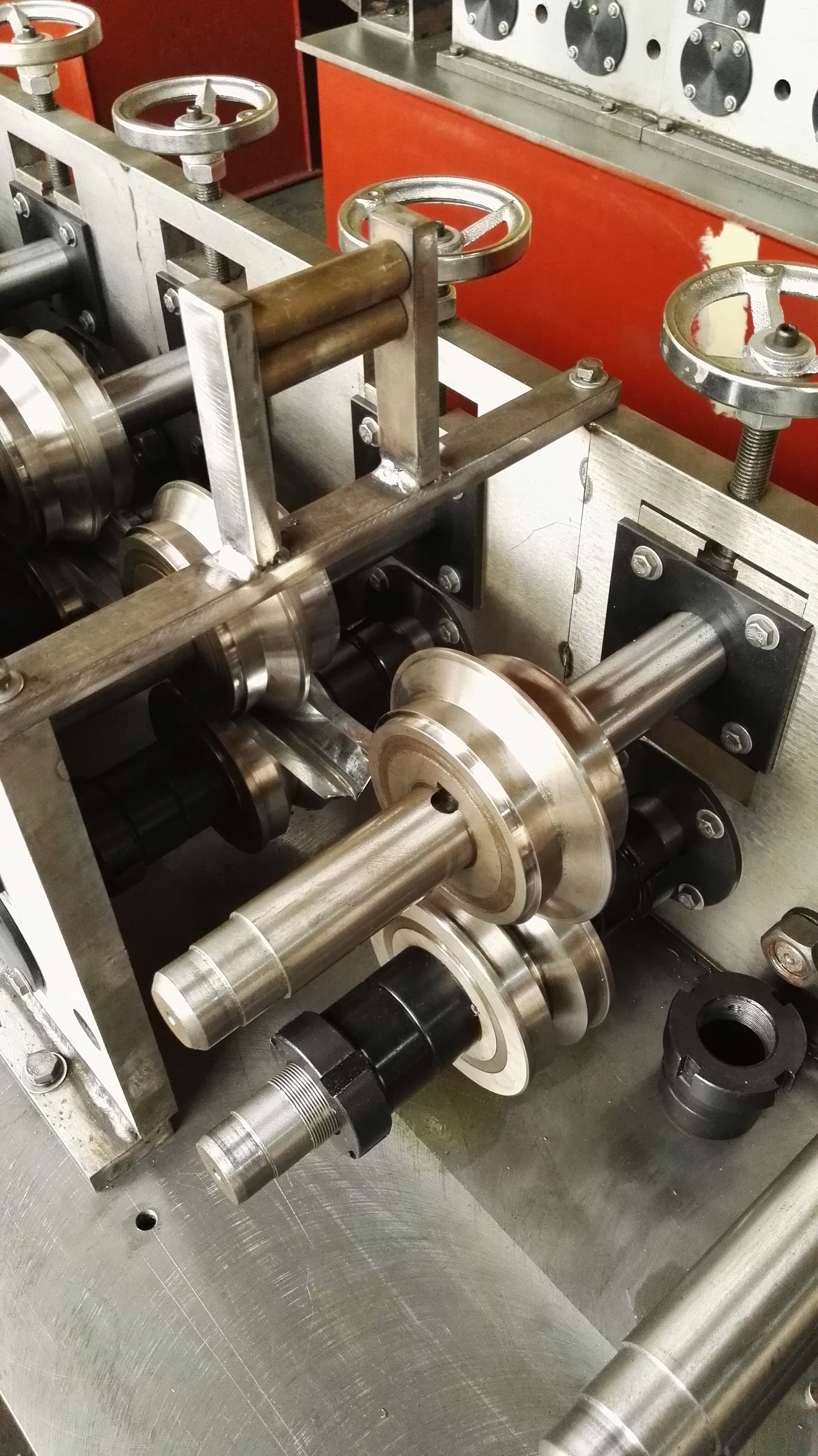

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, Cr12 |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 5.5KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear |

Pictures of machine:

Basic Info

Model No.:YY–ARM—002

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Cutting Mode:Servo Tracking Cutting

Way Of Driven:Gear

Forming Speed:0-45m/min

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

Metal Angle Roll Forming Machine

Metal ceiling Light Keel Roll Forming MachineCeiling Tee bar Making machine Light Keel roll forming machine

Angle Channel Machineis a strip of raw materials, through continuous cold rolling molding, production of complex cross-section profiles, Automatic Angle Roll Forming Machine consists of decoiler, guide rack, forming hosts, calibration device, cut-off part, receiving station, composed of electrical control and so on. Metal Angle Roll Forming Machine is easy to use, easy to operate and so on.

Working process:

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 0-45m/min(without punching) |

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, Cr12 |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 5.5KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear |

Pictures of machine: